Page 29 - 浙江南泵(定稿)

P. 29

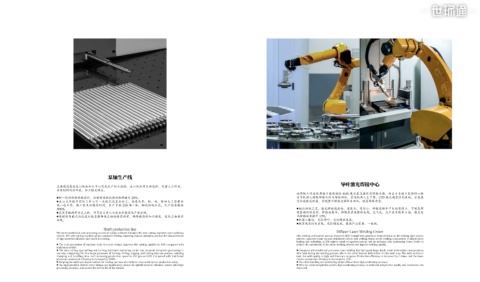

泵轴生产线

主要通过数控走心机和加工中心完成生产加工流程,走心机采用自动送料,代替人工作业, 导叶激光焊接中心

具有材料利用率高,加工稳定特点。

该焊接工作站采用进口德国通快 4kW 激光发生器作为焊接光源,两台日本进口发那科六轴

●新一代的机体结构设计,切削刚性相比传统机种提升 20%。 关节机器人搭配焊接头作为焊接部件,采用机器人上下料、CCD 镜头视觉识别系统、分度盘

●走心式车铣专用加工中心可一次性完成复合加工,使原先车、钻、攻、割四大工序整合 定位旋转送料器,实现整个焊接过程的自动化,提高焊接质量。

成一道工序,减少装夹及搬运时间,生产节拍 250 根 / 班,相比传统工艺,生产效率提高

300%。 ●相比传统工艺,激光焊接速度快、深度大、变形小,焊接过程中产生热量很少,可避免焊

●采用多轴排布方式上料,可节省大量人力成本并提高生产安全性。 缝区域的热变形,焊接面整齐,焊缝质量高整体美观,无气孔。生产效率提升 5 倍,激光电

●高精密内藏式马达设计能显著降低主轴旋转震动量,确保超高的加工精度、延长主轴使用 光转换效率提升 15%。

年限。 ●机器人搬运、定位导叶,定位精准度高。

●配置视觉识别系统,定位精度高,提高产品质量、一致性。

Shaft production line

The entire production and processing process is mainly achieved through CNC wire-cutting machines and machining Diffuser Laser Welding Center

centers. The wire-cutting machine adopts automatic feeding, replacing manual operation, and has the characteristics This welding workstation uses an imported 4kW Trumpf laser generator from Germany as the welding light source,

of high material utilization and stable processing. and two Japanese Fanuc six-axis articulated robots with welding heads as the welding components. It adopts robot

loading and unloading, a CCD camera visual recognition system, and an indexing table positioning rotary feeder to

● The new generation of machine body structure design improves the cutting rigidity by 20% compared with achieve the automation of the entire welding process and improve welding quality.

traditional models.

● The wire-cutting type milling and turning dedicated machining center can complete composite processing in ● Compared with traditional processes, laser welding has fast speed, large depth, small deformation, and produces

one step, integrating the four major processes of turning, drilling, tapping, and cutting into one process, reducing little heat during the welding process, which can avoid thermal deformation in the weld area. The weld surface is

clamping and handling time, and increasing production speed to 250 pieces/shift. Compared with traditional neat, the weld quality is high, and there are no pores. Production efficiency is increased by 5 times, and the laser-

processes, production efficiency is increased by 300%. electric conversion efficiency is increased by 15%.

● Adopting the multi-axis layout method for feeding can save a lot of labor costs and improve production safety. ● The robot handling and positioning of the diffuser have high positioning accuracy.

● The high-precision built-in motor design can significantly reduce the spindle rotation vibration, ensure ultra-high ● With the visual recognition system, high positioning accuracy is achieved, and product quality and consistency are

processing accuracy, and extend the service life of the spindle. improved.