Page 24 - 浙江南泵(定稿)

P. 24

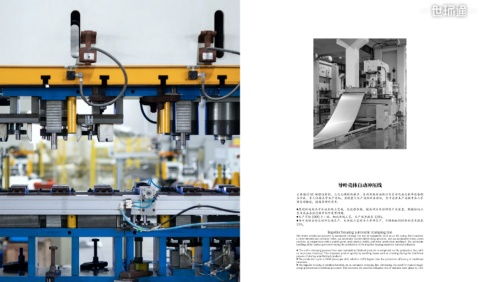

导叶壳体自动冲压线

主要通过 NC 偏摆送料机、三次元横杆机械手、自动双面涂油机以及自动化旋压机等设备配

合冲床、多工位模具等生产母机,实现整个生产过程的自动化,导叶壳体生产过程中各工序

间自动搬运,提高材料利用率。

●原材料到成品冲压流水线上完成,无过程在制。提高冲压件拉伸的产品质量,规避传统工

艺半成品存放过程中的开裂等问题。

●生产节拍 5000 个 / 班,相比传统工艺,生产效率提高 120%。

●导叶壳体全部自动冲压线生产,无传统工艺的手工单冲生产,不锈钢板的材料利用率提高

15%。

Impeller housing automatic stamping line

The entire production process is automated through the use of equipment such as an NC swing feed machine,

a three-dimensional crossbar robot, an automatic double-sided oiling machine, and an automated rotary press

machine, in conjunction with a punch press, multi-station molds, and other production machines. The automatic

handling of the various processes during the production of the impeller housing improves material utilization.

● The entire stamping process from raw materials to finished products is completed on the production line, with

no in-process inventory. This improves product quality by avoiding issues such as cracking during the traditional

process of storing semi-finished products.

● The production cycle is 5000 pieces per shift, which is 120% higher than the production efficiency of traditional

processes.

● The impeller housing is produced entirely on an automatic stamping line, eliminating the need for manual single-

stamp production in traditional processes. This increases the material utilization rate of stainless steel plates by 15%.