Page 25 - 浙江南泵(定稿)

P. 25

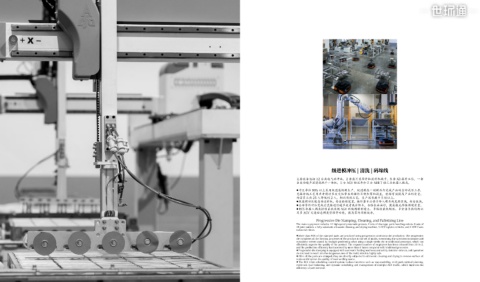

级进模冲压 | 清洗 | 码垛线

主要设备包括 12 台高速气动冲床、2 套盘片类零件取放料机械手、8 套 AB 接料工位,一套

全自动超声波清洗烘干一体机,5 台 AGV 物流车和 2 台 ABB 7 轴工业机器人组成。

●冲压零件 90% 以上采用级进连续模生产,级进模在一副模具内完成产品的全部成形工序,

克服传统工艺用单冲模时多次定位带来的操作不便和累积误差,能够有效提高产品的质量。

所需员工由 25 人降低到 2 人,相比传统工艺,生产效率提升 5 倍以上。

●级进模冲压配自动送料机、安全检测装置,操作者不必将手伸入模具的危险区域,安全性高。

●全部零件冲压完成后直接进行超声波清洗并烘干,去除表面油污,提高激光焊接焊缝质量。

● RCS 机器人调度控制系统实现 AGV 的地图模型建立、多路径最优规划、多任务负载均衡以

及多 AGV 交通动态调度管理等功能,提高零件周转效率。

Progressive Die Stamping, Cleaning, and Palletizing Line

The main equipment includes 12 high-speed pneumatic presses, 2 sets of disc-type parts handling robots, 8 sets of

AB joint stations, a fully automatic ultrasonic cleaning, and drying machine, 5 AGV logistics vehicles, and 2 ABB 7-axis

industrial robots.

● More than 90% of the stamped parts are produced using progressive continuous die production. The progressive

die completes all the forming processes of the product in one set of molds, overcoming the operation invariance and

cumulative errors caused by multiple positioning when using a single-stroke die in traditional processes, which can

effectively improve the quality of the product. The required number of employees has been reduced from 25 to 2,

and the production efficiency has increased by more than 5 times compared with traditional processes.

● Progressive die stamping is equipped with automatic feeding machines and safety detection devices, and operators

do not need to reach into the dangerous area of the mold, which is highly safe.

● After all the parts are stamped, they are directly subjected to ultrasonic cleaning and drying to remove surface oil

stains and improve the quality of laser welding seams.

● The RCS robot scheduling control system realizes functions such as map modeling, multi-path optimal planning,

multi-task load balancing, and dynamic scheduling and management of multiple AGV traffic, which improves the

efficiency of part turnover.