Page 28 - 浙江南泵(定稿)

P. 28

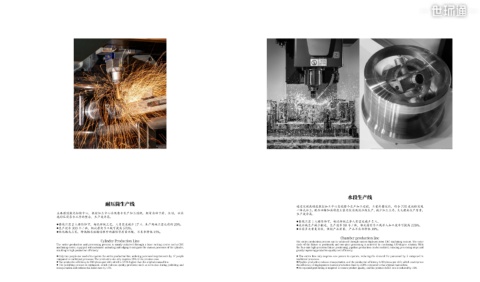

水段生产线

耐压筒生产线

通过定制高精度数控加工中心实现整个生产加工过程,工装外圆定位,结合 720 度旋转实现

一体式加工,配合四轴加高精度工装定位实现流水线生产,减少加工工序,大大提高生产质量,

主要通过激光切割中心、数控加工中心实现整个生产加工过程,配有自动下料、压边,以实 生产效率高。

现耐压筒各个工序的整合,生产效率高。

●整线只需 1 人操作即可,相比传统工序人员需求减少 5 人。

●整线只需 2 人操作即可,相比传统工艺,人员需求减少 17 人 . 生产场地只需之前的 20%。 ●流水线生产减少搬运,生产效率 90 个 / 班,相比原有手工线单人加工效率可提高 220%。

●生产效率 300 个 / 班,相比原有手工线可提高 570%。 ●不需多次重复定位,保证产品质量,产品不良率降低 19%。

●优化抛光工艺,降低抛光运输过程中的擦伤等质量问题,不良率降低 15%。

Chamber production line

Cylinder Production Line The entire production process can be achieved through custom high-precision CNC machining centers. The outer

The entire production and processing process is mainly achieved through a laser cutting center and a CNC circle of the fixture is positioned, and one-piece processing is achieved by combining 720-degree rotation. With

machining center, equipped with automatic unloading and edging to integrate the various processes of the cylinder, the four-axis high-precision fixture positioning, pipeline production can be realized, reducing processing steps and

resulting in high production efficiency. greatly improving production quality and efficiency.

● Only two people are needed to operate the entire production line, reducing personnel requirements by 17 people ● The entire line only requires one person to operate, reducing the demand for personnel by 5 compared to

compared to traditional processes. The production site only requires 20% of the previous area. traditional processes.

● The production efficiency is 300 pieces per shift, which is 570% higher than the original manual line. ●Pipeline production reduces transportation, and the production efficiency is 90 pieces per shift, which can improve

● The polishing process is optimized, which reduces quality problems such as scratches during polishing and the efficiency of single-person manual production lines by 220% compared to the original manual line.

transportation and reduces the defect rate by 15%. ● No repeated positioning is required to ensure product quality, and the product defect rate is reduced by 19%.