Page 10 - 卡麦隆-燃气全焊接球阀

P. 10

Full Welded

www.camvalve.com Full Welded Trunnion Ball Valve Kamailong Valve

Trunnion Ball Valve

全焊接球阀

全焊接球阀

05

06

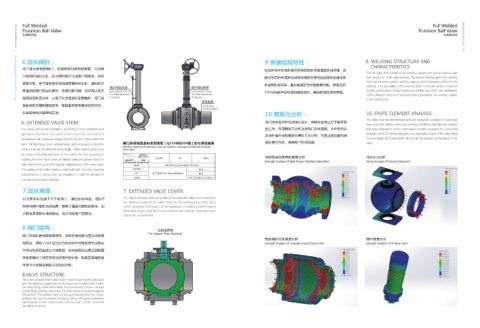

Focus on Manufacturing Welded Ball Valve 6.加长阀杆: 维护用加长管 维护用加长管 左右体与中体的焊接采用典型的窄间隙埋弧多层焊接,焊 9. WELDING STRUCTURE AND

9.焊接结构特性:

CHARACTERISTICS

对于埋地安装的阀门,根据安装和操作的需要,可对阀

The left, right, and middle body welding adopts the typical narrow-gap

门的阀杆进行加长,加长阀杆的尺寸按客户的要求。所有

submerged arc multi-layer welding. The special welding agent and welding

接时采用的专用焊剂具有焊接时所需的载流量和脱渣效果 ,

tools has required current-carrying capacity and degreasing effect for the

的排污管、排气管和紧急注脂装置都相应加长,其他相关

焊层颗粒度较细,满足高强韧性焊缝金属性能。焊缝进行

welding. The granularity of the welding layer is fine and able to meet the

管道紧贴阀门的加长部位,将阀门排污阀、放空阀以及注

Extended Pipe

Extended Pipe

For Maintenance

For Maintenance

100% ultrasonic test and hardness test to guarantee the welding quality

Purpose

Purpose

脂阀接到地面安装,以便于对主阀进行定期维护。阀门表

of the welding line.

焊接袖管 100%的超声波检测和硬度测试,确保焊缝的焊接质量。 metallic performance of high-toughness welding line, which has undertaken

面按规范涂覆耐腐蚀沥青、聚氨酯或者环氧树脂等涂层, Welding

sleeve pipe

以适应埋地安装使用工况。 10. FINITE ELEMENT ANALYSIS

10.有限元分析:

The valve shell and internal elements are designed carefully to make sure

6. EXTENDED VALVE STEM: 阀门壳体及内件经过精心设计,确保在各种工况下能可靠 they may work reliably under any working conditions; finite element analysis

For valves with buried installation, according to the installation and 的工作;采用有限元分析法对阀门壳体强度、内件受力以 has been adopted to conduct simulated condition analysis for valve shell

operation demand, the valve stem could be extended in strength, stress of internal elements, and operating torque of the valve stem,

及阀杆操作扭矩等进行模拟工况分析,为易出现问题和薄

accordance with customer requirements for the size of the extended improve fragile and weak parts, and ensure the superior performance of the

stem. All discharge pipe, exhaust pipe, and emergency injection 阀门所带袖管道与常用钢管(Q235B和20#钢)的可焊接说明 弱处进行优化,确保阀门性能优越。 valve.

Welding instruction for the sleeve pipe and common steel pipe (Q235B and 20# steel)

device shall all be extended accordingly. Other related pipes shall of the valve

be close to the extended part of the valve for the purpose of 管道材料

Piping material # 球型焊接阀体壳体强度分析 内件应力分析

installing the blow-down valve, air release valve, and grease injection 袖管材料 焊材 Q235B 20 16Mn

Sleeve piping material Welding material Strength Analysis Of Ball-shaped Welding Valve Shell Stress Analysis Of Internal Elements

valve above the ground for regular maintenance of the main valve. WCB J507(E5015),H10Mn2,TIG R40

The surface of the valve shall be coated with anti-corrosion asphalt, Q235B N/A

polyurethane, or epoxy resin as required to meet the demand of 20 # J427(E4315),H08A,H08MnA N/A

16Mn J507(E5015),H10Mn2

underground service condition.

7.加长阀盖: 7. EXTENDED VALVE COVER:

For valves working in low temperature, the extended valve cover increases

对于要求在低温下工作的阀门,通过加长阀盖,增加了

the distance between the valve body and the sealing area of the stem,

阀体和阀杆密封区的距离,避免了温度对密封的影响。加 which prevents the impact of temperature on sealing performance.

Extended height shall be in accordance with relevant standard and

长的高度根据标准的规定,也可根据客户的要求。

customer requirement.

8.阀门结构:

支承板结构

The Support Plate Structure

阀门采用三体侧装锻焊结构,球体采用阀体内置支承板结

筒型阀体壳体强度分析 阀杆强度分析

构固定,消除了由于进口压力推动球体与密封座形成的巨 Strength Analysis Of Cylinder-shaped Valve Shell Strength Analysis Of R Valve Stem

大密封负荷而造成过大的扭矩。球体表面光洁度达到镜面,

并使用镶衬了具有良好自润滑性的衬套,即使在最高的操

作压力下也能达到较小的启闭力矩。

8.VALVE STRUCTURE:

The valve adopts three-piece side-mount forge welding structure

and the sphere is supported by the supporting plate built inside

the valve body, which eliminates the excessive torque caused

by the huge loading seal when the inlet pressure pushes against

the sphere. The surface finish of the sphere reaches the mirror

surface; the use of metallic bushing lining with good lubrication

also ensures small open/close torque even under maximal

operating pressure.