Page 8 - 卡麦隆-燃气全焊接球阀

P. 8

阀门的设计和制造特点

Full Welded

www.camvalve.com KAMAILONG全焊接球阀设计和制造按照API 6D规范,阀门的试验和检验按API 6D/API 598的规 Trunnion Ball Valve Kamailong Valve

全焊接球阀

定,阀门的防火试验按API 607和BS6755的规定.阀门的结构采用内置支承板结构,根据阀体的形

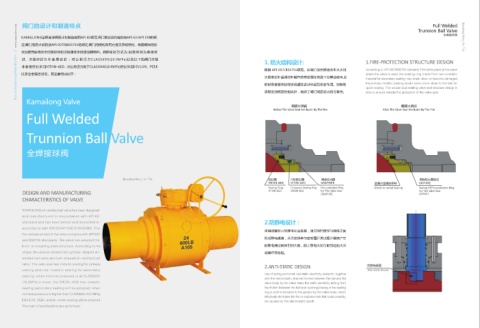

状分圆筒型阀体全焊接球阀和球型阀体全焊接球阀两种。阀座密封方式为:初级密封为金属密 1. 防火结构设计: 1.FIRE-PROTECTION STRUCTURE DESIGN 01

02

Focus on Manufacturing Welded Ball Valve 非金属密封采用VITON-AED , 对公称压力高于CLASS600(10.0MPa)密封采用DEVLON、PEEK 根据 API 607/BS6755规范。在阀门使用现场发生火灾时, According to API 607/BS6755 standard, if fire takes place at the place

封、次级 密 封 为 非 金 属 密 封 ; 对 公 称 压 力CLASS600(10.0MPa)以及以下的阀门次级

where the valve is used, the sealing ring made from non-metallic

以及全金属密封等。其主要特点如下:

次级密封非金属材料制作的密封圈在高温下分解或破坏,此

material for secondary sealing may break down or become damaged,

the primary metallic sealing would soon come close to the ball for

时初级金属密封能够迅速贴紧球体起到密封作用。独特的

quick sealing. The unique dual sealing valve seat structure design is

Kamailong Valve 双级密封阀座结构设计,确保了阀门阀座防火的可靠性。 able to ensure reliable fire protection of the valve seat.

阀座火烧前 阀座火烧后

Before The Valve Seat Are Burnt By The Fire After The Valve Seat Are Burnt By The Fire

Full Welded

Trunnion Ball Valve

全焊接球阀

Kamailong Valve 01 06 密封圈 O型密封圈 阀座防火圈 阀座防火圈密封

VITON AED VITON AED GRAPHITE 金属对金属的密封 GRPHITE

Sealing Ring O-shaped Sealing Ring Fire-protection Ring Metal-to-metal Sealing Sealing Of Fire-protection Ring

DESIGN AND MANUFACTURING VITON AED VITON AED For The Valve Seat For The Valve Seat

GRPHITE

GRAPHITE

CHARACTERISTICS OF VALVE

KAMAILONG all-welded ball valve has been designed

and manufactured in accordance with API 6D

standard and has been tested and inspected in 2.防静电设计:

accordance with API 6D/API 598 STANDARD. The

采用弹簧和小球静电引出装置,通过阀杆使球与阀体之间

fire resistance test of the valve complies with API 607

形成静电通道,从而使球体与密封圈开关过程中摩擦产生

and BS6755 standards. The valve has adopted the

built-in mounting plate structure. According to the 的静电通过阀体引到大地,防止静电火花可能引起的火灾

shape, the valve is divided into cylinder-shaped all- 或爆炸等危险。

welded ball valve and ball-shaped all-welded ball

valve. The valve seat has metallic sealing for primary 防静电装置

2.ANTI-STATIC DESIGN:

sealing and non-metallic sealing for secondary Anti-static Device

Use of spring and small-ball static electricity extractor, together

sealing; when nominal pressure is at CLASS600

with the electrostatic channel formed between the ball and the

(10.0MPa) or lower, the VITON-AED non-metallic valve body by the valve stem, the static electricity arising from

sealing secondary sealing will be adopted; when the friction between the ball and opening/closing of the sealing

ring is able to be taken to the ground by the valve body, which

nominal pressure is higher than CLASS600 (10.0 MPa),

effectively eliminates the fire or explosion risk that could possibly

DEVLON, PEEK, and all-metal sealing will be adopted. be caused by the electrostatic spark.

The main characteristics are as follows: