Page 14 - 绿源通膜壳样册

P. 14

LVYUANTONG

绿源通 常州绿源通玻璃钢压力容器有限公司

绿源通

注意事项 拆卸说明

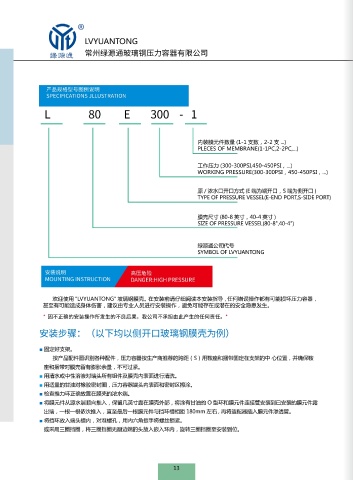

产品规格型号图例说明 ◇ 按照配件表检查有无遗漏部件; ◇ 拆卸前确认所有压力来源都已关闭,并确保膜壳内部

SPECIFICATIONS JLLUSTRATION 压力已完全释放;

◇ 推力环和承压板组件是否组装到位;

◇ 确保推力环在浓水端; ◇ 拆除与源 / 浓水端口以及净水口所有的直接连接;

L 80 E 300 - 1 ◇ 检查连接件 ( 拷贝林,卡箍 ) 安装到位; ◇ 用内六角扳手,将挡环的螺丝退出,用皮锤敲击端板

◇ 上述事项无疏漏后,开始缓慢向容器加压,排除残留空气。 使挡环松动。

使用维护指导

内装膜元件数量 (1-1 支数,2-2 支 ...) ♦ 使用温度在 -7℃ ~49℃ , 严禁超出此温度范围的条件下工作。壳体能承受的 PH 值范围为 3~10;

PLECES OF MEMBRANE(1-1PC,2-2PC,...) ♦ 背压不可超出 125PSL ( 0.88Mpa );

♦ 不可接触禁用的有机溶液;

工作压力 (300-300PSI,450-450PSI,...) ♦ 严禁在系统工作时对膜壳进行拆卸;

WORKING PRESSURE(300-300PSI,450-450PSI,...) ♦ 膜壳不得作为承重载体,不能在其上部载重或施加重力,不能对其直接连接的配件施加压力;

♦ 严禁在超过设计压力的条件下长期工作。

原 / 浓水口开口方式 (E 端为端开口,S 端为侧开口 ) ♦ Welcome to use "LVYUANTONG" FRP membrane housing.Please read this instruction before mounting.Failure to follow

TYPE OF PRESSURE VESSEL(E-END PORT,S-SIDE PORT) these guidelines and neglect every precaution may result in malfunction,even damage to human beings.Therefore,we

recommend that only qualified and experienced person can handle these vessels to avoid potential security risk!

* Damage due to improper operation or installing is the sole responsibility of the purchaser. *

膜壳尺寸 (80-8 英寸,40-4 英寸 )

SIZE OF PRESSURE VESSEL(80-8",40-4") Steps: (Illustrate by side port FRP membrane housing)

♦ Fix the frame well.

Identify every accessories according to the Accessory Drawing ,to mount the shell on the center of the frame with saddles and straps

绿源通公司代号 in accordance with the spans(S) suggested by factory.Assure that saddles and straps leave space for the expansion of the shell.The

SYMBOL OF LVYUANTONG bolts should not be so tight.

♦ Using a mild solution to clean each end of the vessel liner surface;rinse away all loosened deposits from the shell inside surface

using fresh water.

♦ Using glycerin to lubricate the rubber seal ring,the inside of the head and the seal area.

安装说明 高压危险 ♦ Check that the thrust cone is installed on the concentrate side.

MOUNTING INSTRUCTION DANGER:HIGH PRESSURE ♦ Load the membrane element clockwise into the upstream end of the vessel.Leave a few inches of the membrane element projection

from the vessel to facilitate interconnection to the next membrane element,the assemble the inter-connector O-ring covered with

glycerin to the loaded element,then one by one to be pushed forward until the distance between the last membrane element and the

欢迎使用 "LVYUANTONG" 坡璃钢膜壳。在安装前请仔细阅读本安装指导,任何错误操作都有可能损坏压力容器, ring groove is around 180mm.Then install the adaptor into the membrane permeate tube.

甚至有可能造成身体伤害,建议由专业人员进行安装操作,避免可能存在或潜在的安全隐患发生。

♦ Put the securing blocks into the groove then install and fasten the screws with the inside hexangular wrench.

Note:

* 因不正确的安装操作所发生的不良后果,我公司不承担由此产生的任何责任。*

♦ Check for missing parts according to the spare parts list;

安装步骤:(以下均以侧开口玻璃钢膜壳为例) ♦ The proper installation of thrust cone and bearing plate;

♦ Make sure the trust cone is on the side of concentrate port.

■ 固定好支架。 ♦ Check all piping connections(Coupling and hoop) to ensure that they will provide a leak-tree seal;

♦ After completing the above pre-pressurization checks, vessel should be filled slowly to assist air in escaping.

按产品配件图识别各种配件,压力容器按生产商推荐的跨距(S)用鞍座和捆带固定在支架的中 心位置,并确保鞍

座和捆带对膜壳留有膨胀余量,不可过紧。 Removing Instruction:

■ 用清水或中性溶液对端头所有组件及膜壳内表面进行清洗。 ♦ Release pressure.Shut off all sources of pressure and release pressure from the shell.

♦ Disconnect and remove feed/concentrate port.

■ 用适量的甘油对橡胶密封圈,压力容器端头内表面和密封区擦涂。 ♦ Remove the screws from the security blocks with the inside hexangular wrench.Then use leather hammer to strike the sealing plate

■ 检查推力环正确放置在膜壳的浓水端。 to make the sealing blocks loose.

■ 将膜元件从源水端顺向推入,保留几英寸露在膜壳外部,将涂有甘油的 O 型环和膜元件连接管安装到已安装的膜元件露 Maintenance Guide:

出端,一根一根侬次推入,直至最后一根膜元件与挡环槽相距 180mm 左右 , 再将适配器插入膜元件渗透管。 ♦ Operation temperature is -7℃ ~ 49℃ ,he allowable water PH range is 3~10.

■ 将挡环放入端头槽内,对准螺孔,用内六角扳手将螺丝锁紧。 ♦ Abnormal back pressure should not above 125PSI(0.88Mpa).

♦ Do not use banned organic solutions.

或采用三圈挡圈,将三圈挡圈无翻边端的头放入嵌入环内,旋转三圈挡圈至安装到位。 ♦ Forbid to remove shell under working conditions.

♦ The shell should not be used as a support.Do not apply undue force lo any spare parts connected directly.

♦ Can not be operated exceeding design pressure for a long time.

13 14