Page 36 - 卡麦隆-燃气全焊接球阀

P. 36

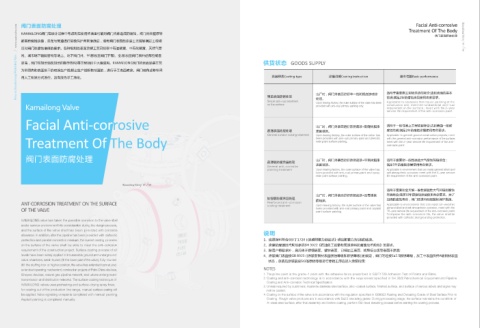

Facial Anti-corrosive

www.camvalve.com 阀门表面防腐处理 Treatment Of The Body Kamailong Valve

KAMAILONG阀门在设计过程中考虑到在使用环境里可能对阀门壳体造成的腐蚀,阀门壳体壁厚等

阀门表面防腐处理

都留有腐蚀余量,且在与管道进行阴极保护并联措施后,现有阀门表面的涂装工艺能够满足工程项

目对阀门防腐蚀措施的要求。各种级别的表面涂装工艺已经在中石油装置、中石化装置、天然气管 57 58

Focus on Manufacturing Welded Ball Valve 更高,阀门带加长颈及加长的操作机构)等工程项目中大量应用。KAMAILONG阀门的表面涂装工艺 供货状态 GOODS SUPPLY 涂装说明Coating instruction 基本性能Basic performance

网、城市地下输配管网等地上、地下阀门井、半埋地(至阀门下部)、全埋地(至阀门填料函部位或者

为带预热和表面烘干的喷涂生产线;超出生产线规格范围的,进行手工表面喷涂。阀门暗角或修补采

涂装种类Coating type

用人工刷涂方式进行。沥青漆为手工涂刷。

简单表面防锈处理

防锈;满足2年防腐蚀涂层使用寿命要求。

处理。

Simple anti-rust treatment 出厂时,阀门外表面进行单一的防锈底漆喷涂 适用于需要施工现场涂漆的场合;达到表面的基本

Applicable to occasions that require painting at the

Upon leaving factory, the outer surface of the valve has been

Kamailong Valve on the surface provided with anti-rust primary painting only. construction site; meet the fundamental anti-rust

requirement on the surface; meet with the 2-year

service life requirement of the anti-corrosion paint.

Facial Anti-corrosive 出厂时,阀门外表面进行防锈底漆+酚醛树脂漆 适用于一般性地上工程项目场合;达到表面一般耐

普通表面涂层处理 表面喷涂。 腐蚀性能;满足2年防腐蚀涂层使用寿命要求。

General surface coating treatment Upon leaving factory, the outer surface of the valve has Applicable to general ground construction projects; meet

Treatment Of The Body resin paint surface painting. with the general anti-corrosion performance of the surface;

been provided with anti-rust primary paint and phenolic

meet with the 2-year service life requirement of the anti-

corrosion paint.

阀门表面防腐处理 出厂时,阀门外表面进行防锈底漆+环氧树脂漆 适用于需要耐一般性碱盐大气腐蚀环境场合 ;

普通级防腐涂层处理

表面喷涂。 满足5年防腐蚀涂层使用寿命要求。

General anti-corrosion

painting treatment Upon leaving factory, the outer surface of the valve has Applicable to environment that can resist general alkali and

been provided with anti-rust primary paint and epoxy salt atmospheric corrosion; meet with the 5-year service

resin paint surface painting. life requirement of the anti-corrosion paint.

Kamailong Valve 57 58

适用于需要耐全天候一般性碱盐性大气环境耐腐蚀

出厂时,阀门外表面进行防锈底漆+沥青漆表 环境场合;满足10年防腐蚀涂层使用寿命要求。为了

加强级防腐涂层处理 面喷涂。 加强防腐蚀寿命,阀门应进行阴极接地保护措施。

ANT-CORROSION TREATMENT ON THE SURFACE Reinforced anti-corrosion Upon leaving factory, the outer surface of the valve has Applicable to environment that can resist all-weather

coating treatment

OF THE VALVE been provided with anti-rust primary paint and asphalt general alkali and salt atmospheric corrosion; meet with the

10-year service life requirement of the anti-corrosion paint.

paint surface painting.

To improve the anti-corrosion life, the valve shall be

provided with cathodic and grounding protection.

KAMAILONG valve has taken the possible corrosion to the valve shell

under service environment into consideration during the design process,

and the surface of the valve shell has been provided with corrosion

allowance. In addition, after the pipeline has been provided with cathodic 说明

protection and parallel connection measure, the current coating process 1、底层涂料符合GB/丁1720 ((漆膜附着力测定法》规定附着力为1级的底漆。

on the surface of the valve shall be able to meet the anti-corrosion 2、涂装防腐蚀技术规范参照SH 3022《石油化工设备和管道涂料防腐蚀技术规范》的要求。

requirement of the construction project. Surface coating process of all 3、除用户有要求外,奥氏体不锈钢表面、镀锌表面、已精加工表面、铭牌标志版等表面不涂漆;

levels have been widely applied in innumerable ground and underground 4、涂装阀门表面按GB 8923 ((涂装前钢材表面锈蚀等级和除锈等级))的规定,阀门毛坯按Sa2.5除锈等级,加工中表面保持A级钢材表面

valve chambers, semi-buried (till the lower part of the valve), fully-buried

状态,总装后涂装前按St3的除锈等级进行除锈工序后进入涂装程序;

(till the stuffing box or higher position, the valve has extended bonnet and

extended operating mechanism) construction projects of Petro China devices, NOTES

Sinopec devices, natural gas pipeline network, and urban underground 1. The prime paint is the grade-1 paint with the adhesive force prescribed in GB/T1720 Adhesion Test of Paints and Films.

transmission and distribution networks. The surface coating technique of 2. Coating and anti-corrosion technology is in accordance with the requirement specified in SH 3022 Petrochemical Equipment and Pipeline

Coating and Anti-corrosion Technical Specification.

KAMAILONG valves uses preheating and surface-drying spray lines;

3. Unless required by customers, Austenite stainless steel surface, zinc-coated surface, finished surface, and surface of various labels and signs may

for coating out of the production line range, manual surface coating will not be coated;

be applied. Valve vignetting or repair is completed with manual painting. 4 .Coating on the surface of the valve is in accordance with the regulation specified in GB8923 Rusting and Derusting Grade of Steel Surface Prior to

Asphalt painting is completed manually. Coating. Rough valve products are in accordance with Sa2.5 derusting grade. During processing stage, the surface maintains the condition of

A-class steel surface; after final assembly and before coating, perform St3-level derusting process before starting the coating process.