Page 34 - 卡麦隆-燃气全焊接球阀

P. 34

www.camvalve.com Kamailong Valve Butt-welding Kamailong Valve

Ends

对接焊端

Butt-welding

53

54

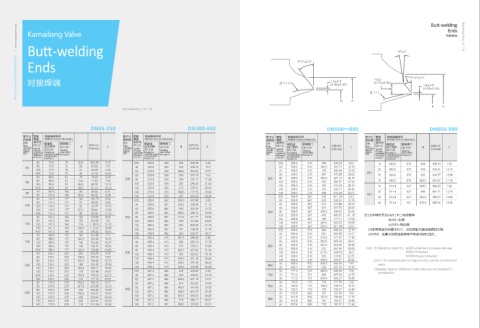

Focus on Manufacturing Welded Ball Valve Ends 注(1) 37.5 +2.5 o 1.6+0.8 19+2 37.5 +2.5 1.6+0.8

o

o

o

对接焊端

(0.75+0.06)

(0.06+0.03)

(0.06+0.03)

B A 注(1)

B A

Kamailong Valve 53 54

DN65-250 DN300-450 DN500一800 DN850-900

管子公 管壁 焊接端部外径 管子公 管壁 焊接端部外径 管子公 管壁 焊接端部外径 管子公 管壁 焊接端部外径

称规格 厚度 Welded-end out diameters 称规格 厚度 Welded-end out diameters 称规格 厚度 Welded-end out diameters 称规格 厚度 Welded-end out diameters

DN 系列号 锻造或 铸钢阁门 DN 系列号 锻造或 铸钢阁门 DN 系列号 锻造或 铸钢阁门 DN 系列号 锻造或 铸钢阁门

Pipe 注(1) 加工组件 注(2)A B C 注(3) t Pipe 注(1) 加工组件 注(2)A B C 注(3) t Pipe 注(1) 加工组件 C 注(3) Pipe 注(1) 加工组件 C 注(3)

nominal Seried C Note(3) nominal Seried C Note(3) nominal Seried 注(2)A B t nominal Seried 注(2)A B t

specifi- of pipe 注(1)A Casting specifi- of pipe 注(1)A Casting specifi- 注(1)A Casting C Note(3) specifi- 注(1)A Casting C Note(3)

cation schedule Forged or steel valve cation schedule Forged or steel valve cation of pipe steel valve cation of pipe steel valve

DN DN DN schedule Forged or DN schedule Forged or

thikness manufactured Note(2) A thikness manufactured Note(2) A thikness manufactured Note(2) A thikness manufactured Note(2) A

components

components

note(1) note(1) components components

Note(1) A Note(1) A note(1) Note(1) A note(1) Note(1) A

40 73.0 75 62.5 662.93 5.16 STD 323.8 329 305 306.08 9.53 STD 508.0 516 489 490.28 9.53 10 863.6 876 848 848.70 7.92

80 73.0 75 59 59.69 7.01

65 40 323.8 329 303 304.72 10.3 XS 508.0 516 482.5 484.74 12.70

160 73.0 75 54 55.28 9.35 XS 323.8 329 298.5 300.54 12.71 40 508.0 516 478 480.55 15.09 20 863.6 876 848 840.34 12.70

XXS 73.0 75 45 47.43 14.02 323.8 329 295 297.79 14.2 60 508.0 516 467 470.88 20.62 850 30 863.6 876 832 834.77 15.88

40 88.9 91 78 78.25 5.49 300 60 323.8 329 289 292.17 17.48 500 80 508.0 516 455.5 461.13 26.19

80

80 80 88.9 91 73.5 74.53 7.62 100 508.0 516 443 450.02 32.54 40 863.6 876 828.5 831.97 17.48

160 88.9 91 66.5 68.38 11.13 100 323.8 329 281 285.24 21.44 120 508.0 516 432 440.29 38.10 10 914.4 927 898.5 889.50 7.92

XXS 88.9 91 58.5 61.19 15.24 120 323.8 329 273 278.31 25.40 140 508.0 516 419 429.17 44.45

40 101.6 105 90 90.52 5.74 140 323.8 329 266.5 272.75 28.58 20 914.4 927 889 891.14 12.70

90 160 508.0 516 408 419.44 50.01

80 101.6 105 85.5 86.42 8.08 160 323.8 329 257 264.25 33.35 STD 558.8 567 539 541 .08 9.53 900 30 914.4 927 882.5 885.57 15.88

40 114.3 117 102 102.73 6.02 STD 355.6 362 336.5 337.88 9.53 XS 558.8 567 533 535.54 12.70

80 114.3 117 97 98.28 8.56 558.8 567 514 518.86 22.23 40 914.4 927 876.5 880.02 19.05

100 120 114.3 117 92 93.78 11.13 40 355.6 362 333.5 335.08 11.13 40

501

160 114.3 117 87.5 89.65 13.49 XS 355.6 362 300 332.34 12.70 60 558.8 567 488.5 507.75 28.58

80

34.93

567

496.63

558.8

XXS 114.3 117 80 83.30 17.12 60 355.6 362 325.5 328.15 15.09 550 注:(1)字母代号为:(a)S丁D二标准壁厚

40 141.3 144 128 128.80 6.55 350 80 355.6 362 317.5 321.22 19.05 100 558.8 567 476 485.52 41 .28

80 141.3 144 122 123.58 9.3 100 355.6 362 308 312.86 23.83 120 558.8 567 463 474.41 47.63 (b)XS=加厚

125 120 141.3 144 116 1 18.04 12.70 120 355.6 362 300 305.93 27.79 140 558.8 567 450.5 463.30 53.98 (c)XXS=特加厚

160 141 .3 144 109.5 1 12.47 15.88 140 355.6 362 292 299.00 31.75 160 558.8 567 590.5 591 .88 9.53 (2)所列直径为非要求尺寸,此处列出为使用者提供方便。

XXS 141.3 144 103 106.92 19.05 STD 609.6 619 584 586.34 12.70

40 168.3 172 154 154.82 7.11 160 355.6 362 284 292.07 35.71 XS 609.6 619 581 583.59 14.27 (3)DN5。及更小规格连续垫环不考虑内部机加工。

80 168.3 172 146.5 148.06 10.97 STD 406.4 413 387.5 388.68 9.83 40 609.6 619 574.5 577.97 17.48

150 120 168.3 172 140 142.29 14.27 40 406.4 413 381 383.14 12.70 60 609.6 619 560.5 565.49 24.61

160 168.3 172 132 135.31 18.26 60 406.4 413 373 376.21 16.66 600 80 609.6 619 547.5 554.38 30.96

XXS 168.3 172 124.5 128.85 21.95 80 406.4 413 363.5 367.84 21.44 100 609.6 619 532 540.49 38.89 Note: (1)Characters stand for: (a)STD=Standard schedule thikness

40 219.1 223 203 203.75 8.18 400 100 406.4 413 354 359.53 26.19 120 609.6 619 517.5 528.03 46.2 (b)XS=Thickened

60 219.1 223 198.5 200.02 1031 120 406.4 413 344.5 351.18 30.96 140 609.6 619 505 516.91 52.37 (c)XXS=Super thickened

80 219.1 223 193.5 195.84 12.70 140 406.4 413 333.5 341.43 36.53 160 609.6 619 490.5 504.37 59.54 (2)A11 the diameters are not reguired size, just be convenient for

200 100 219.1 223 189 191.65 15.09 160 406.4 413 325.5 334.50 40.49 650 10 660.4 670 645.5 645.50 7.92 users

120 219.1 223 182.5 186,11 18.26 20 660.4 670 635 637.14 12.70 (3)Gasket rings for DN50 and below Size are not consided to

140 219.1 223 178 181.98 20.62 STD 457.2 464 438 439.48 9.53 10 711.2 721 695.5 696.30 7.92 manufacture.

XXS 219.1 223 174.5 179.16 22.23 40 457.2 464 432 433.94 12.70 700 20 711.2 721 686 687.94 12.70

160 219.1 223 173 177.79 23.01 XS 457.2 464 428.5 431.19 14.27 30 711.2 721 679.5 682.37 15.88

40 273.0 278 254.5 255.74 9.27 60 457.2 464 419 422.82 19.05 10 762.0 772 746 747.10 7.92

60 273.0 278 247.5 249.55 12.70 80 457.2 464 409.5 414.46 23.83 750 20 762.0 772 736.5 738.74 12.70

80 273.0 278 243 245.55 15.09 450 30 762.0 772 730 733.17 15.88

250 100 273.0 278 236.5 240.01 18.26 100 457.2 464 398.5 404.78 29.36 10 812.8 825 797 797.90 7.92

120 273.0 278 230 234.44 21.44 120 457.2 464 387.5 395.03 34.93 800 20 812.8 825 787.5 789.54 12.70

140 273.0 278 222 227.51 25.40 140 457.2 464 378 386.77 39.67 30 812.8 825 781 783.97 15.88

160 273.0 278 216 221 .95 28.58 160 457.2 464 366.5 376.99 45.24 40 812.8 825 778 781.17 17 48