Page 5 - 湖北深紫科技有限公司----产品样册

P. 5

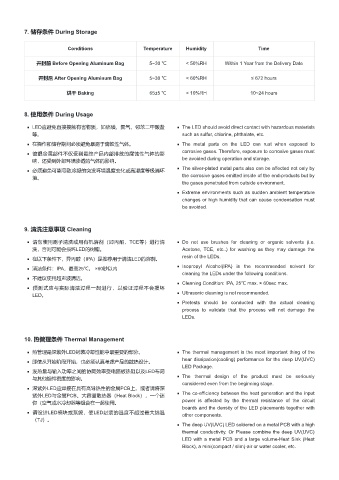

7. 储存条件 During Storage

Conditions Temperature Humidity Time

开封前 Before Opening Aluminum Bag 5~30 ℃ < 50%RH Within 1 Year from the Delivery Date

开封后 After Opening Aluminum Bag 5~30 ℃ < 60%RH ≤ 672 hours

烘干 Baking 65±5 ℃ < 10%RH 10~24 hours

8. 使用条件 During Usage

LED应避免直接接触有害物质,如硫磺,氯气,邻苯二甲酸盐 The LED should avoid direct contact with hazardous materials

等。 such as sulfur, chlorine, phthalate, etc.

在操作和储存期间必须避免暴露于腐蚀性气体。 The metal parts on the LED can rust when exposed to

镀银金属部件不仅受到最终产品内部排放的腐蚀性气体的影 corrosive gases. Therefore, exposure to corrosive gases must

响,还受到外部环境渗透的气体的影响。 be avoided during operation and storage.

必须避免可能导致冷凝的突发环境温度变化或高湿度等极端环 The silver-plated metal parts also can be affected not only by

境。 the corrosive gases emitted inside of the end-products but by

the gases penetrated from outside environment.

Extreme environments such as sudden ambient temperature

changes or high humidity that can cause condensation must

be avoided.

9. 清洗注意事项 Cleaning

请勿使用刷子清洗或用有机溶剂(即丙酮,TCE等)进行清 Do not use brushes for cleaning or organic solvents (i.e.

洗,否则可能会损坏LED的树脂。 Acetone, TCE, etc..) for washing as they may damage the

在以下条件下,异丙醇(IPA)是推荐用于清洁LED的溶剂。 resin of the LEDs.

清洁条件:IPA,最高25℃。 ×60秒以内 Isopropyl Alcohol(IPA) is the recommended solvent for

cleaning the LEDs under the following conditions.

不建议使用超声波清洁。

Cleaning Condition: IPA, 25℃ max. × 60sec max.

预测试应与实际清洁过程一起进行,以验证过程不会损坏

LED。 Ultrasonic cleaning is not recommended.

Pretests should be conducted with the actual cleaning

process to validate that the process will not damage the

LEDs.

10. 热管理条件 Thermal Management

热管理是深紫外LED封装冷却性能中最重要的部分。 The thermal management is the most important thing of the

即使从开始阶段开始,也必须认真考虑产品的散热设计。 hear dissipation(cooling) performance for the deep UV(UVC)

LED Package.

发热量与输入功率之间的协同效率受电路板热阻以及LED布局

与其他组件密度的影响。 The thermal design of the product must be seriously

considered even from the beginning stage.

深紫外LED应焊接在具有高导热性的金属PCB上。或者请将深

紫外LED与金属PCB、大容量散热器(Heat Block),一个迷 The co-efficiency between the heat generation and the input

你(空气或水冷却器等组合在一起使用。 power is affected by the thermal resistance of the circuit

boards and the density of the LED placements together with

请设计LED模块或系统,使LED封装的温度不超过最大结温 other components.

(TJ)。

The deep UV(UVC) LED soldered on a metal PCB with a high

thermal conductivity. Or Please combine the deep UV(UVC)

LED with a metal PCB and a large volume-Heat Sink (Heat

Block), a mini(compact / slim)-air or water cooler, etc.